Published on October 26th, 2019 | by admin

0Hydraulic Power Packs: An Overview

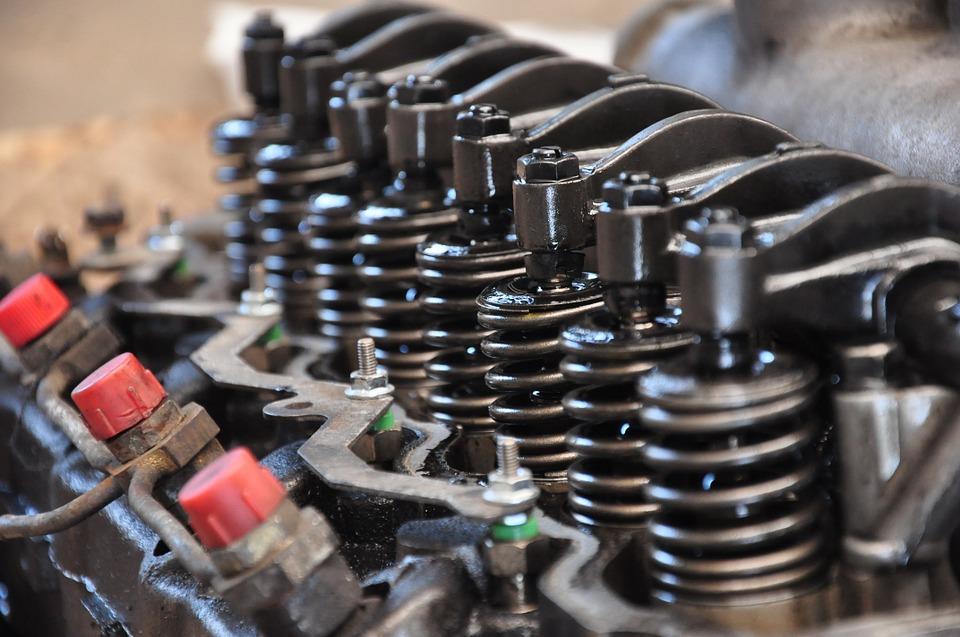

Portability is an essential feature of most hydraulic machinery. In any application where there is no integrated hydraulic power source, a hydraulic power pack produces the force needed to operate the machine. These compact power units come with various capacities to suit different machine requirements.

Hydraulic power packs – general description

Instead of using a built-in power supply, hydraulic power packs are convenient, compact, and self-contained. These power packs range in size from large and stationary units to micro units suitable for smaller applications. However, regardless of the difference in size, every hydraulic power pack has the same essential components. These components are:

- Pump

- Regulator

- Motor

- Reservoir

- Pressure supply line

- Pressure relief line

Some hydraulic power packs may also have additional components such as:

- Cooler and heater. Temperature regulation may be necessary to prolong the life of the hydraulic power pack.

- Controller. The controller is the interface which contains switches, buttons, and levers, which the operator uses to control the power pack.

- Filter. Contaminants that enter the hydraulic pump contribute to wear and tear. Filtering these contaminants ensures that the hydraulic pack functions efficiently for longer.

- Pressure control valve. This valve controls the amount of pressure within the system.

- Directional control hydraulic valve. This valve directs the movement of hydraulic fluid within the system.

Hydraulic power packs also have accumulators that collect oil coming from the pump. The accumulator helps in maintaining fluid pressure, supplementing the function of the motor.

Factors that affect the hydraulic power unit’s performance

Apart from varying capacities and sizes, hydraulic power units also differ according to specific performance parameters. These parameters are reservoir volume, power capacity, and pressure limit. Other physical characteristics, such as the unit size and pumping strength, are also crucial in choosing the right power pack for the intended application. Most reputable suppliers ensure that they have a range of hydraulic power packs that can withstand the rigours of specific environmental conditions.

Other factors to consider in buying hydraulic power packs

In addition to the considerations and factors discussed above, you also need to choose a power pack according to specified valve connections. Selecting the right valve connection means the hydraulic power pack is versatile enough to power a variety of machines. To make it easier for consumers, manufacturers typically label their products as either macro, mini, standard, or customised.

When is customisation necessary?

While most hydraulic power packs available off the shelf suit a variety of machines, there are instances when a bespoke model is more appropriate. Customisation depends on specific features you want to add to your machine. For example, you can have a separate power pack to operate a mixer and another power pack for the drop door. Ultimately, it depends on circumstances and conditions unique to the application.

In conclusion, hydraulic power packs are supposed to consume less power, take up little space, and operate under a minimal cooling requirement. The purpose of using a hydraulic power pack is to increase efficiency and at the same time minimise operational cost. These are critical factors you need to consider in choosing a hydraulic power pack.